Description

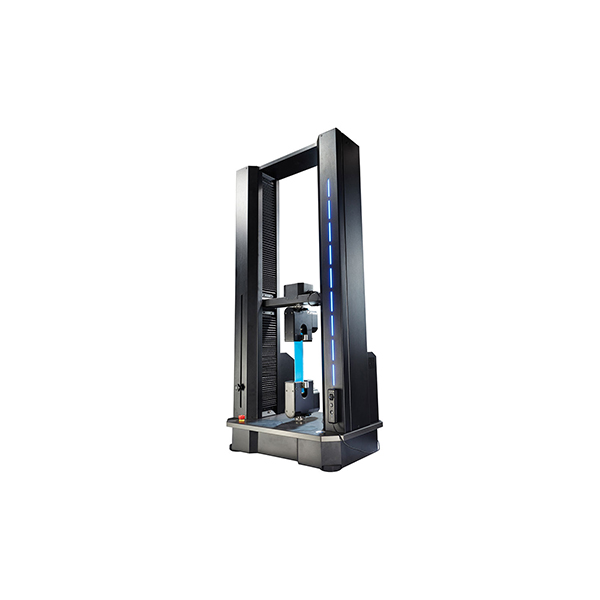

Titan is a Universal Strength tester which has been designed for accuracy, efficiency and ease of use. Tensile testing is used to understand and determine the maximum load that a material can withstand. The sample is subjected to a controlled tension until failure. Examples of properties that can be measured with Titan include, ultimate tensile strength, breaking strength, maximum elongation and reduction in area.

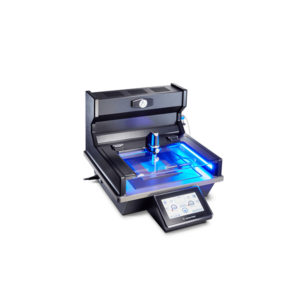

Titan can test a range of applications including:

- Yarns

- Fabrics

- Seams

- Shoes

- Ropes

- Straps

Titan10 is also a dual column instrument, meaning larger samples can be tested across a full range of tests including tension, compression, stretch & recovery, tear, peel, adhesion peel and other applications. It has a vertical test space of 1200mm and a space between columns of 460mm.

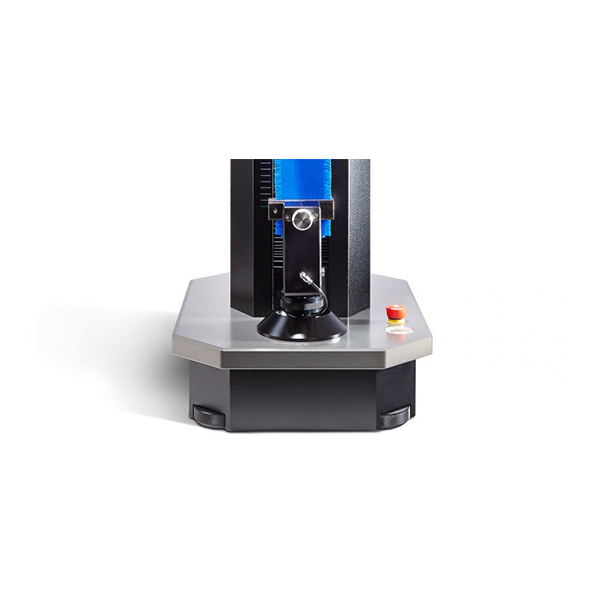

Titan has the flexibility to allow the operator to control the instrument manually through the hand-held controller, the SMART button or on screen. The hand-held controller enables ‘at instrument’ control for effortless sample loading, this is especially useful when positioning and gripping specimens of variable or irregular size.

Standards

- AS 2001.2.10-1986

- AS 2001.2.21-1986

- AS 2001.2.22-2006

- AS 2001.2.3.1-2001

- AS 2001.2.3.2-2001

- ASTM D3787-1

- ASTM D1578-93 (2016)

- ASTM D1682-64 (1975)

- ASTM D1683-11a

- ASTM D1876-08 (2015)

- ASTM D1894-14

- ASTM D1938-08

- ASTM D2061-07

- ASTM D2207-00 (2010)

- ASTM D2208-00 (2010)

- ASTM D2209-00 (2010)

- ASTM D2211-00 (2010)

- ASTM D2212-00 (2010)

- ASTM D2256-10 (2015)

- ASTM D2261-13

- ASTM D2262-83

- ASTM D2724-07 (2015)

- ASTM D3167-10

- ASTM D3354-11

- ASTM D3759M-05 (2011)

- ASTM D4034-92

- ASTM D434-95

- ASTM D4533-11

- ASTM D4632-08

- ASTM D4704-12

- ASTM D4830-06

- ASTM D4831-00 (2010)

- ASTM D4833-07

- ASTM D4846-96 (2004)

- ASTM D4851-07 (2015)

- ASTM D4912-07

- ASTM D4964-96 (2016)

- ASTM D5034-09 (2013)

- ASTM D5035-11 (2015)

- ASTM D5169-98 (2010)

- ASTM D5170-98 (2010)

- ASTM D5587-15

- ASTM D5733-99

- ASTM D5735-95 (2001)

- ASTM D5748-07

- ASTM D5822-08

- ASTM D5884-04a (2010)

- ASTM D6077-10

- ASTM D6241-04 (2009)

- ASTM D6479-12

- ASTM D6614-07 (2015)

- ASTM D6636-01 (2011)

- ASTM D6775-02 (2007)

- ASTM D6797-15

- ASTM D7005-03 (2008)

- ASTM D7142-05

- ASTM D7506-12

- ASTM D751 Section 18

- ASTM F1917-2012

- ASTM F963-11 (Tension Test for Seams)

- ASTM F963-11 (Tension Test)

- ASTM D6644-01 (2013)

- ASTM D1335 (IP units)

- ASTM D751 (Section 32)

- BIS IS 14625 Annex D

- BIS IS 14181 (Part 2)

- BIS IS 15891 (Part 4)

- BIS IS 6489 (Part 2)

- BIS IS 7016 (Part 2)

- BIS IS 7071 (Part 4)

- BIS IS 7703 (Part 2)

- BIS IS 6489 (Part 3)

- BIS IS 6489 (Part 4)

- BIS IS 7016 (Part 3)

- BIS IS 7016 (Part 5)

- BIS IS 1969

- EN ISO 11644:2009 (IUF 470)

- EN ISO 13934-1:2013

- EN ISO 13934-2:2014

- EN ISO 13935-1:1999

- EN ISO 13935-1:2014

- EN ISO 13935-2:1999

- EN ISO 13935-2:2014

- EN ISO 13935/6-2

- EN ISO 13936-1:2004

- EN ISO 13936-2:2004

- EN ISO 13936-3:2007 (Apparel)

- EN ISO 13936-3:2007 (Upholstery)

- EN ISO 13937-2:2000

- EN ISO 13937-3:2000

- EN ISO 13937-4:2000

- EN ISO 1421:1998

- EN ISO 17695:2005

- EN ISO 17708:2003

- EN ISO 2062:2009

- EN ISO 23910:2007 (IUP 44)

- EN ISO 2411:2000

- EN ISO 3376:2011 (IUP 6)

- EN ISO 3377-2:2002 (IUP 8)

- EN ISO 3386-1:2015

- EN ISO 4674-1:2003 – Method A

- EN ISO 4674-1:2003 – Method B

- EN ISO 9073-4:1997

- EN ISO 17698:2013

- ISO 11857:1999

- ISO 17696:2004

- ISO 17697:2003 Method A

- ISO 17697:2003 Method B

- ISO 17706:2003

- ISO 1805:1973

- ISO 2023:1994 Annex C

- ISO 20866:2001

- ISO 20872:2001

- ISO 20874:2001

- ISO 29864:2007

- ISO 3303:1990 Method A

- ISO 3379: 1976

- ISO 4578:1997

- ISO 4637:1979 (BS 903-A27:1986)

- ISO 4919:2012

- ISO 5081:1977

- ISO 5082:1982

- ISO 6939:1988

- ISO 8124-1:2012

- ISO 8124-1:2012 (Compression Test)

- ISO 8124-1:2012 (Tension Test)

- ISO 9073-3:1989

- ISO 9073-5:2008

- JIS L1085:1998 (2013)

- JIS L1085:1998 (2013) (6.7.3)

- JIS L1086:2007 (superseded)

- JIS L1093:2011 Grab Method A-1

- JIS L1093:2011 Grab Method A-2

- JIS L1093:2011 Grab Method A-3

- JIS L1096:2010 (8.14.1)

- JIS L1096:2010 (8.14.2)

- JIS L1096:2010 (8.15.1)

- JIS L1096:2010 (8.15.2)

- JIS L1096:2010 (8.16.1)

- JIS L1096:2010 (8.17.1)

- JIS L1096:2010 (8.17.2)

- JIS L1096:2010 (8.23.1) Method A

- JIS L1096:2010 (8.23.1) Method B

- JIS L1096:2010 (8.23.1) Method C

- JIS L1096:2010 (8.23.1) Method D

- JIS L1096:2010 (8.23.2) Method B

- JIS L1096:2010 (8.23.3)

- JIS L1085 (6.5.1)

- M&S P12A

- M&S P11

- M&S P115

- M&S P115A

- M&S P115B

- M&S P115C

- M&S P115H

- M&S P11A

- M&S P11B

- M&S P11C

- M&S P12

- M&S P122

- M&S P124

- M&S P12B

- M&S P12C

- M&S P13

- M&S P13A

- M&S P14

- M&S P141

- M&S P14A

- M&S P14B

- M&S P14C

- M&S P15 PART 1

- M&S P15A

- M&S P15B

- M&S P35

- M&S P42

- M&S P43

- M&S P70

- M&S P98

- NEXT TM16

- NEXT TM16a

- NEXT TM21

- NEXT TM21a

- NEXT TM25

- NEXT TM27

- NEXT TM36

- NEXT TM37

- NEXT TM42

- NEXT TM45

- NEXT TM46

- adidas® Group 4.10

- adidas® Group 4.11

- adidas® Group 4.12 Version 01

- adidas® Group 4.13 Version 02

- adidas® Group 4.14

- adidas® Group 4.15

- adidas® Group 4.27 Version 03

- adidas® Group ST-05 (07.06.11)

- adidas® Group ST-07

- Adidas® Group 4.40

- Arcadia AG29 (07.12)

- Arcadia AG30 (07.12)

- Arcadia AG31 Part(i) (07.12)

- Arcadia AG36 (07.12)

- Arcadia AG37 (07.12)

- Arcadia AG38 (07.12)

- Arcadia AG39 (07.12)

- FZ/T 70005-2006 – 7.1.1

- FZ/T 70005-2006 – 7.1.2

- FZ/T 70006-2004 – 8.2.1 and 8.4

- FZ/T 70006-2004 – 8.2.2

- FZ/T 70006-2004 – 8.3.1.1

- FZ/T 70006-2004 – 8.3.1.2

- FZ/T 70006-2004 – 8.3.2.1

- FZ/T 70006-2004 – 8.3.2.2

- FZ/T 80007.1-2006

- FZ/T 81004-2003

- FZ/T 81006-2007

- FZ/T 81007-2012

- FZ/T 81008-2004

- FZ/T 81010-2009

- GB 6675.2-2014 (Compression Test)

- GB 6675.2-2014 (Tension Test for Seams)

- GB 6675.2-2014 (Tension Test)

- GB/T 14272-2002

- GB/T 18132-2002

- GB/T 19976-2005

- GB/T 2660-2008

- GB/T 2662-2008

- GB/T 2664-2009

- GB/T 2665-2009

- GB/T 2666-2009 4.4.10 & Annex B-T

- GB/T 2666-2009 4.4.11 & Annex C-T

- GB/T 3916-2013

- GB/T 3923.1-2013

- GB/T 3923.2-2013

- QB/T 2711-2005

- SC/T 4022-2007

- GB/T 3917. 2-2009

- GB/T 3917.3-2009

- GB/T 3917.4-2009

- GB/T 3917.5-2009

- EN 12311-1:1999

- EN 12332-1:1998

- EN 12773:1999

- EN 13514:2001

- EN 13522:2001

- EN 13571:2001

- EN 13572:2001 Method A

- EN 13572:2001 Method B

- EN 14410:2003

- EN 1464:2010

- EN 14704-1

- EN 14704-2 Method A

- EN 14704-3 Method A

- EN 15598:2008

- EN 1875-3:1997

- EN 29073-3:1992

- EN 388:2016 – Puncture Resistance (6.4)

- EN 388:2016 – Tear Resistance (6.3)

- EN 71-1 (Compression Test: 110N)

- EN 71-1 (Seam Test)

- EN 71-1 (Tension Test)

- EN 1392: 1992

- EN 14716:2004

- SABS SM 637:2000

- AATCC 136-2009

- AATCC/ASTM TS-010

- AATCC/ASTM TS-015

- AATCC/ ASTM D1335 (IP Units)

- DS-275/B

- DS-275/C

- DS-275/D

- DS-160 – TEST 1

- DS-160 – TEST 2

- DS-160 – TEST 3

- DS-160 – TEST 4

- DECATHLON DS-044

- Decathlon DS-302

- BS 1932-2:1989

- BS 2543:1995

- BS 2576:1986

- BS 3084:2006

- BS 3144:1968 – Ball Burst Test

- BS 3320:1988 (1995)

- BS 3424 Part 33 Method 36

- BS 3424:Part 4:1982 Method 6

- BS 3424:Part 5:1982 Method 7A

- BS 3424:Part 5:1982 Method 7B

- BS 3424:Part 5:1982 Method 7C

- BS 3424:Part 6:1982

- BS 3424:Part 7:1982

- BS 4162:1983

- BS 4303:1968

- BS 4952:1992

- BS 5131-3.1:1991

- BS 5131-5.11:1981

- BS 5131-5.13

- BS 7907:2007 (Annex B)

- BS 8510:2009 (Section 10)

- 16 CFR 1500.51-53 Tension Test

- DUPONT TTM 076 (2000)

- GAP INC S1023 (05/12/09)

- GAP INC S1027

- GAP INC S1028

- GAP INC S1033 (November 2013)

- GAP INC S1034

- GAP INC S1064 (June 2015)

- H&M TM DS:12

- H&M TM DS:13

- INEN 1061:1983

- INEN 561:1981

- Jantzen Test Method 3

- JTA ST 2012 Compression Test

- JTA ST 2012 Tension Test

- LS&CO METHOD 11 (IP units)

- LTD 03 (01/30/2015)

- LTD 06 (05/27/10)

- LTD 07 (05/27/10)

- LTD 16 (05/27/10)

- LTD 18 (05/27/10)

- LTD 24 (05/27/10)

- LTD 26 (05/27/10)

- LTD 27 (05/27/10

- LTD 81 (based on 16 CFR 1500.53)

- LTD 84 Part 1 (04/12/2016)

- LTD 84 Part 2 (04/12/2016)

- LTD 10

- LTD 11

- LTD 15

- LTD 19

- NIKE DRAFT – Stretch & Elastic Properties – Part 1

- NIKE DRAFT – Stretch & Elastic Properties – Part 2

- NIKE TEST G76 for Binding Tape

- NIKE TEST G76 for Cables

- NIKE TEST G76 for Elastic Gore

- NIKE TEST G76 for Fabrics

- NIKE TEST G76 for Genuine Leathers

- NIKE TEST G76 for Insole Boards

- NIKE TEST G76 for Knitted Mesh

- NIKE TEST G76 for Shoe Laces

- NIKE TEST G76 for Synthetic Leathers

- NIKE TEST G76 for Threads

- NIKE TEST G76 for Webbings

- NIKE TEST G76 for Yarns

- NIKE TEST G77 – Textile

- Nike Test EQ01

- PSTC-131

- Renault D41 1015/–E

- SATRA PM117

- SATRA TM29

- SATRA TM30: 1995

- SIS 25 12 31 – 1970

- TEMA ELASTICITY FT-07 Method 2

- Triumph TP-22

- UNE 40902:2008

- UNI 10606:2009

- UNI 4818-11:1992

- UNI 4818-7:1992

- DBA RMQT-OI/020-035 Rev 01

- ERT 20.2-89

- ERT 70.4-99

- PB-001

- PB-002

- PB-003

- PB-004

- PB-021

- PB-027

- PB-028

- NWSP 100.2

- NWSP 110.5

- NWSP 100.3

- NWSP 110.1

- NWSP 110.4

- NWSP 401.0

- PRIMARK PM07

- PRIMARK PM08

- TOYOTA ENG. Std. TSL3505G

- TARGET TP 50&51

- Lululemon-001 (IP Units)

- Lululemon-001 (SI Units)

- Lululeomon-002 (IP Units)

- Lululeomon-002 (SI Units)

- CPSD-SL-24964-MTHD

James Heal Instruments Physical Testing